What are Bioplastics? Biobased and biodegradable plastics

Today there are many things that are bio: bio-fruit, bio-meat, bio-fuel, bio-clothing even bio-hotels. However, few have heard of bioplastics. Perhaps you have unknowingly held a bioplastic in your hand? We answer the question what bioplastics are, what makes them so special and where they are already used.

What are bioplastics? Raw materials and their properties

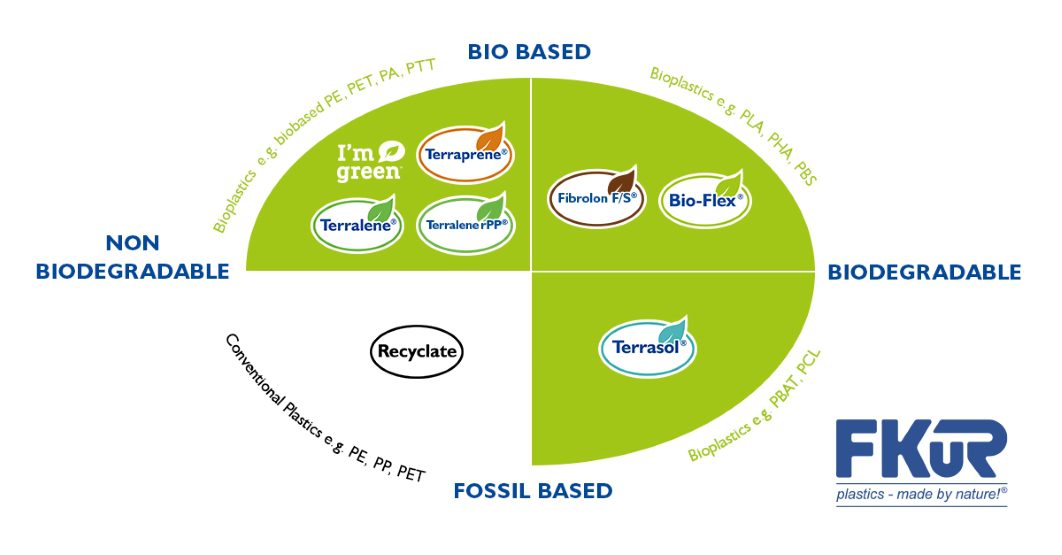

The word bioplastics does not refer to a single material, but to a whole family of different plastics that are distinguished by their raw material base and properties. On the one hand, there are bioplastics that are made entirely or partly from renewable raw materials, but whose properties do not necessarily differ from conventional plastics. On the other hand, all plastics are called bioplastics because of their property of being biodegradable/compostable. In this case, the raw material base is irrelevant.

Accordingly, there are three product groups that all belong to the bioplastics:

- Bio-based, non-biodegradable bioplastics

- Bio-based, biodegradable bioplastics

- Fossil-based, biodegradable bioplastics

Conclusion: Bioplastics are bio-based, biodegradable or both at the same time.

What are biobased plastics? What does biobased mean?

The term “biobased” is used to describe that part of a material or product that comes from biomass, i.e. renewable raw materials such as starch, sugar cane or cellulose. Biobased plastics are therefore those plastics that are produced partly or completely from biomass.

Is biobased the same as biodegradable?

There are both bio-based plastics that are also biodegradable, such as PLA, starch, Bio-Flex® and Ceroflex®. As well as bio-based plastics that are not biodegradable. Also known as drop-in bioplastics, these materials have an identical chemical structure to their fossil counterparts. This allows them to be recycled in established systems along with fossil plastics. Examples include Bio-PE (I’m green polytehylene), Bio-PET (Eastlon), Terralene®, Terraprene®, etc.

Conclusion: bio-based plastics may or may not be biodegradable.

What are biodegradable plastics?

Biodegradation describes a natural process in which a material is broken down into its components, especially carbon dioxide and water. If a plastic is biodegradable, it is completely broken down by microorganisms into carbon dioxide, water and biomass, leaving no harmful or toxic residues. In terms of the time required, this term is not further defined. The process of biodegradation depends largely on environmental conditions (e.g. location or temperature), the material itself and the applications. Biodegradability in soil can be substantiated by corresponding certificates and test seals such as “OK biodegradable soil” or “DIN tested biodegradable in soil”.

What are compostable plastics?

Bioplastics may be called compostable if they meet all the criteria for demonstrating compostability in accordance with standard EN 13432 or ASTM D 6400, irrespective of their raw material base (renewable or petrochemically based). For this purpose, the degradation process must take place in a defined time under environmental conditions that correspond to those within an industrial composting plant. In colloquial terms, composting is biological degradation in fast motion under optimized conditions.

Conclusion: Whether a material is biodegradable or compostable has nothing to do with its raw material source. Biodegradable and compostable plastics can be bio-based or fossil-based.

How is the compostability of a plastic or product tested?

Biodegradable plastics are considered compostable if they degrade completely within a specified period of time. DIN EN 14995 defines the compostability of plastics in general. DIN EN 13432 specifies the compostability of packaging. The requirements set are the same for both standards and are made up as follows:

- Analysis of biodegradation – at least 90% of the polymer mass must have been converted to carbon dioxide within 180 days (approx. 6 months);

- Analysis of disintegration during biological treatment. After three months (12 weeks) in industrial or semi-industrial composting conditions, there should be a sufficient level of disintegration, i.e. mechanical disintegration of the plastic (no more than 10% dry mass should remain on a sieve < 2 mm). Any residues will also be completely converted to CO2, water and biomass by microorganisms in the further course of time.

- Ecotoxicity analysis to show that the biological treatment has not reduced the quality of the compost. This is verified by a plant growth test on compost with biodegraded and disintegrated polymer compared to growth on “normal” compost.

- Content of heavy metals and other elements below the limits listed in Annex A.

If the bioplastic or the product made from it passes the above mentioned tests, it is certified as industrially compostable according to EN 13432 or DIN EN 14995 (English equivalent ASTM D 6400). Attention: the industrial compostability is related to a certain maximum layer thickness.

How do I recognize a bioplastic?

Bioplastics are either bio-based, biodegradable or both at the same time. The sole labeling as “bioplastic” is therefore often ambiguous. The use of test seals from recognized institutions makes it possible to characterize bioplastics or to identify the origin of the raw materials. In addition to the test seals for biodegradable and compostable plastics, which have been in use for some time, there are also seals for bioplastics made from renewable raw materials.

What technological advantages do bioplastics offer over petroleum-based plastics?

Thanks to their specific properties, bioplastics enable processors to open up new areas of application. Depending on the application, they show alternatives to petrochemical-based plastics and have already become firmly established in many applications.

In addition to their image, modern bioplastics have a variety of additional functions that generate added value in end products. In addition to the properties mentioned above, bioplastics offer further technical advantages compared to conventional plastics. These include natural breathability and a natural “soft touch”, which gives films made from bioplastics a pleasant feel. Alternative disposal options are also an advantage. The possibility of recycling bioplastics after their use phase in composting plants or through energy recovery are decisive points here. Bio-based plastics in particular can make a contribution to the efficient use and conservation of resources, since their main components are renewable.

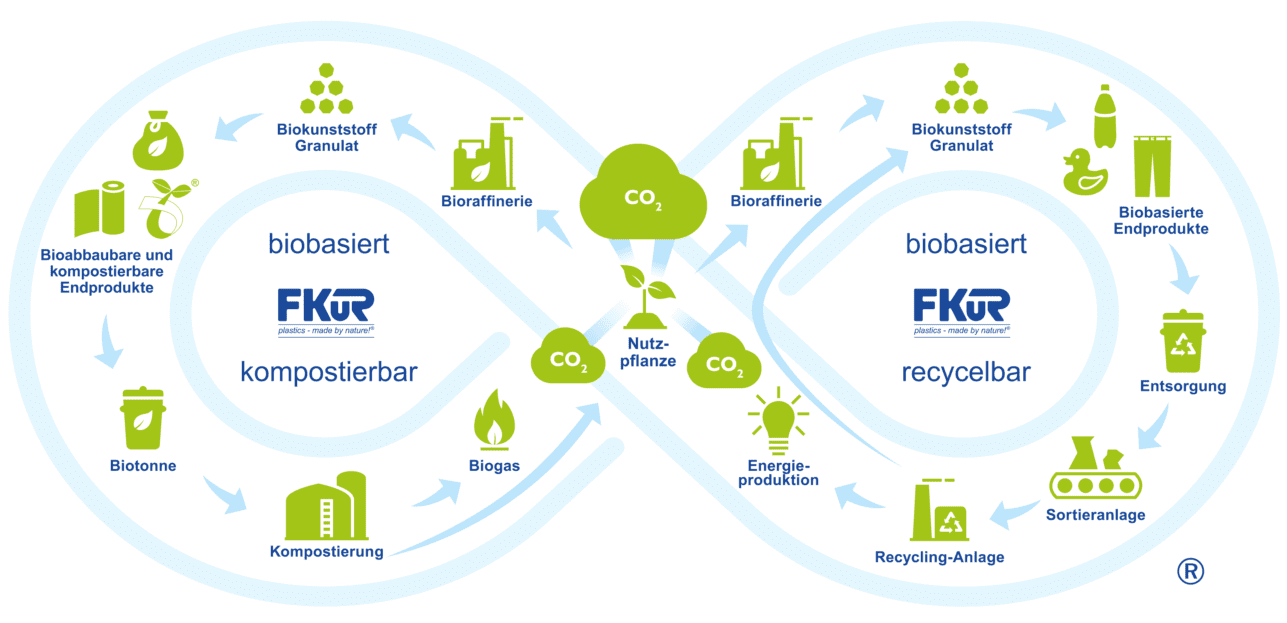

How do bioplastics support the circular economy and resource conservation?

The fundamental rule is that plastic – including bioplastics – should never be carelessly dumped in the environment. Littering is a fundamental flaw in the way we humans are being educated and behave. Bioplastics cannot change that and are not a solution to littering problem. However, in some areas, biodegradable plastics can add value. For example, in plastic products that are designed to remain in nature.

Responsible use of our natural resources also applies to bioplastics: The less material used, the better for nature and people. Industry, trade and consumers alike are called upon to use plastics responsibly, to reuse them, dispose of them, recycle them and ultimately to recycle them properly.

Bioplastics are a sustainable alternative to petroleum-based plastics, especially if their renewable raw material base is obtained sustainably and bioplastics are consistently recycled. This includes both the recyclable material cycle and the organic cycle of composting. Above all, clear labeling and communication regarding the properties of the bioplastic – bio-based, biodegradable or both – is essential.

Bioplastics – a new and at the same time old class of materials

Bioplastics have already been produced industrially in the 19th century and were thus the first industrially produced mass plastics. One of the first bio-based plastics was celluloid. A thermoplastic based on cellulose, it was mainly used for films, toys or eyeglass frames. Later, “Cellophane”, also based on cellulose, was developed, a plastic that is still familiar to many today. Cellophane was primarily used in the packaging industry.

Until the 1930s, plastics were primarily produced from renewable raw materials. It was not until the discovery and industrial production of plastics based on fossil raw material sources such as crude oil and natural gas that these early bioplastics were replaced. Only from the 1980s onwards were there again significant developments in the field of bio-based plastics. This development was primarily due to a change in ecological awareness. The aim was (and still is) to use renewable raw materials to close material cycles and conserve resources.

Today, we are noticing the effects with increasing intensity: the world is facing a scarcity of resources. The global population is growing, but the demand for the same finite raw materials is continuously increasing. It is undeniable that we humans are living beyond our means and pushing our planet to the breaking point.

Therefore, the shift from a linear to a circular economy is an important step to address these challenges. Bioplastics play an essential role in this! But first, let’s clarify what bioplastics are.

On-demand webinar: Bioplastics – basics, circular economy, and practical examples

Get concise, easy-to-understand insights into bio-based and biodegradable plastics (bioplastics) and their advantages and disadvantages, differences, standards (e.g., DIN EN 13432, EN 14995), and specific areas of application. Watch it flexibly now, start at any time, and ask specific questions afterwards.

Knowledge that drives progress-

Access the webinar now for free!

Watch the webinar recording for free and benefit today from our free know-how.

No time or missed the webinar?

Here’s how to access our free webinar recording:

- Fill out the form and click on "Get the recording now".

- Check your inbox and confirm your email address.

- You will receive the link to the recording by email from us.

Would you like to get an overview of our bioplastic granulates?

Bioplastics meet recycling: Bioplastic compounds with recycled content

A bio-recyclate hybrid combines the strengths of bio-based plastics and recyclates (recycled plastics). The use of bio-based components replaces fossil-based plastics, which helps to conserve limited resources.

In addition, bio-recycled hybrids comply with the EU packaging regulation (PPWR) and help companies meet legal requirements while making progress towards carbon neutrality. Our bioplastic compounds with recycled content are specially optimized for injection moulding processing.