Plastic housings from Bioplastics

Engineering bioplastics for a customized and sustainable housing.

We are happy to help.

Sales team

High-performance engineering bioplastics for strong, durable plastic housings

A good casing combines intelligent and functional design with practicality and an aesthetic appearance. Nowadays, only 50% of device housings correspond to a standard housing, as manufacturers increasingly sell individual or customized systems. With an original design and functionality, you create a unique selling proposition to effectively stand out from the competition.

Whether standard housings, housings for electrical or electronic articles, computer or peripheral housings, switch boxes or connector housings. All plastic housings have one thing in common: they must meet high mechanical, physical and thermal requirements. The selection of the right plastic is therefore all the more important. Classically, fossil plastics such as polystyrene (PS), acrylonitrile-butadine-styrene co-polymer, in short ABS, polycarbonate (PC) are used.

Produce injection molded housings from renewable raw materials

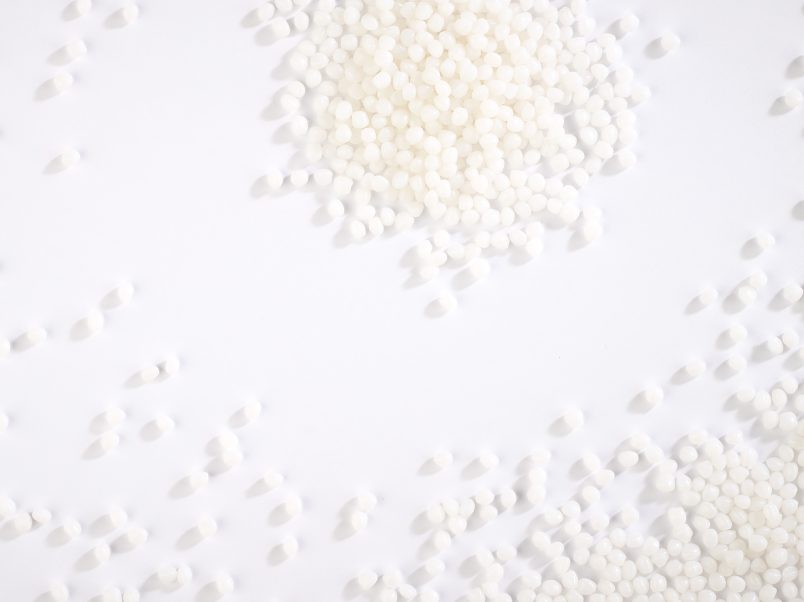

We offer you a wide range of different bio-based, injection-moldable plastic granules. These meet a wide spectrum of requirements in terms of their technical properties. For example, you can choose between particularly heat-resistant, impact-resistant or chemical-resistant bioplastics.

Housing made of biodegradable Bio-Flex® or the bio-based Biograde®

Our injection molding grades of the Bio-Flex® and Biograde® families have similar properties to ABS or polystyrene and can be processed by injection molding on existing molds. All granules are based predominantly on renewable raw materials. The grades of the Bio-Flex® product line are biodegradable or compostable, whereas impact-modified, UV-stabilized and glass-fiber-reinforced grades are offered under the name Biograde®.

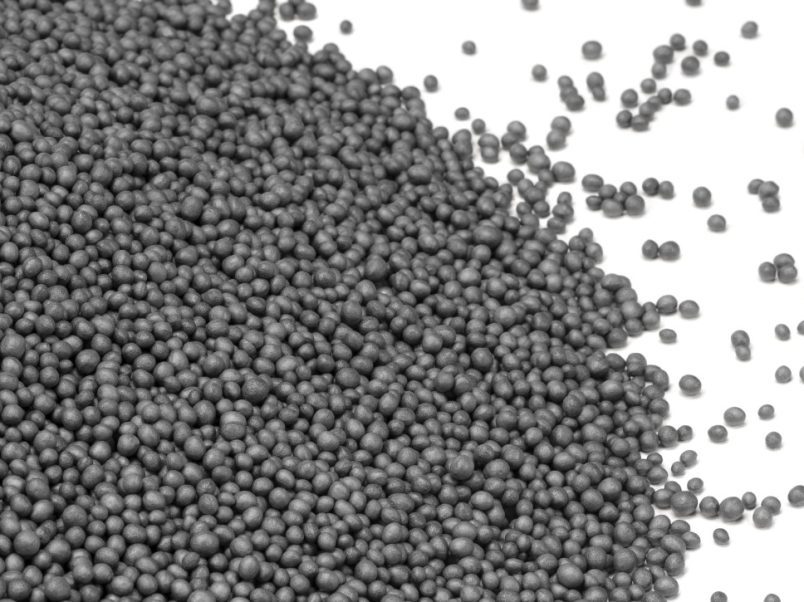

Natural fiber-reinforced plastics (NFP) for housings with a wooden look

The wood fiber-reinforced WPC plastics Fibrolon® and Terralene® WF can be used to produce high-quality surfaces with a defined wood feel. This gives enclosures and components made from our NFP bioplastics an individual character and natural appearance. It both looks and feels like wood, but unlike wood, Fibrolon® and Terralene® WF can also be injection molded into complex structures and design components.