Terralene rPP

Terralene® rPP - hybrid compounds based on polypropylene (PP) recyclate and renewable raw materials.

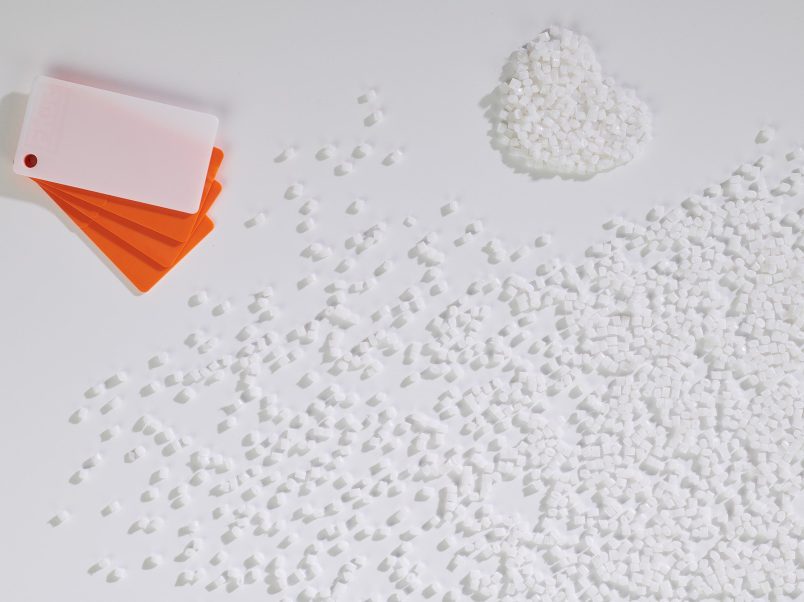

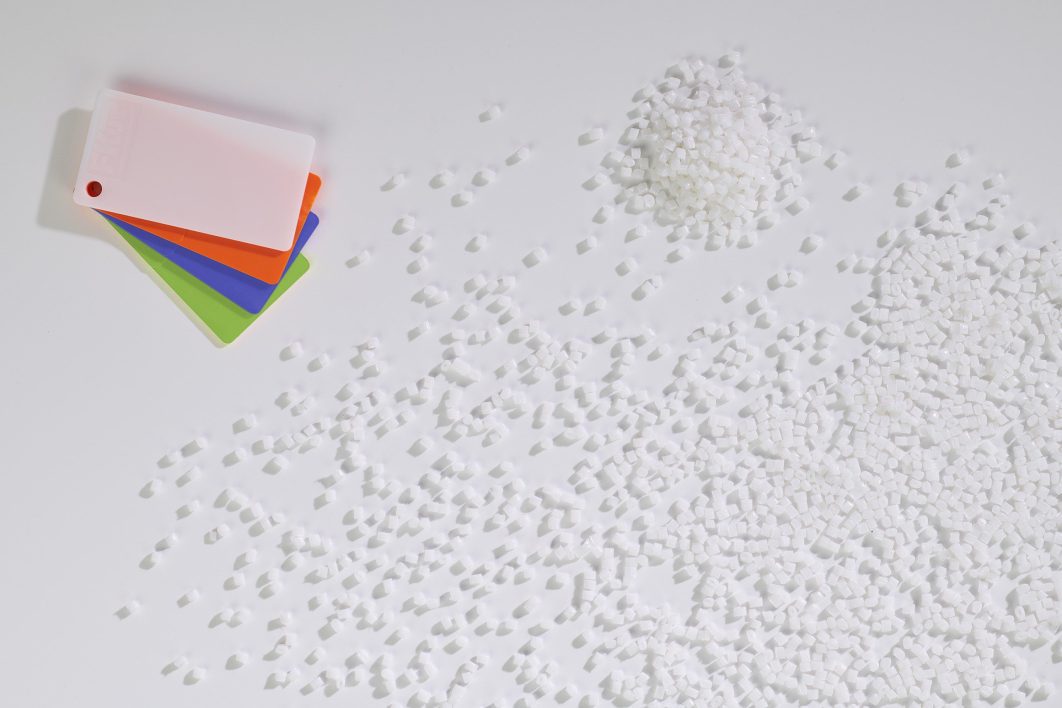

Terralene® rPP combines the best of both worlds, bringing together PCR recyclates with renewable raw materials. The special feature is that all grades are natural to whitish in color and can be dyed in a variety of ways and are excellent recyclable. Typical applications are injection molding and extrusion products in the non-food sector.

Highlights of our Terralene rPP

compounds made from PCR recyclate and renewable raw materials conserve fossil resources

contains up to 33% renewable resources

easy processable on existing equipment

despite their high recycled content, granules are natural or whitish in color

With Terralene rPP the following products can be made:

Plastics recycling: valuable source of raw materials for optimum resource conservation

The earth cannot produce raw materials as fast as humans consume them. Our resources are not infinite. That’s why we turn plastic waste into valuable resources by incorporating recycled polymers into our bio-based PP compounds: Terralene® rPP compounds are hybrids that combine recyclates and bio-based raw materials while being fully recyclable. These compounds offer the advantage that technical properties can be adjusted even more consistently and process performance can be optimized. This results in tailor-made products for a wide range of applications at a high technical level, although these are currently still limited to the non-food sector.

FKuR-Terralene-rPP-3505-Rezyklat-Biokunststoff-Hybrid

High-quality PCR recyclates that can be colored in a variety of ways

“Grey is the new white” is often the headline when it comes to the subject of recyclates. But not at FKuR: All compounds of the Terralene® rPP product range are characterized by a natural to white appearance. This means they can be colored in a variety of ways and offer manufacturers new possibilities in terms of design freedom.

Conserving resources with recyclates and renewable raw materials

For the production of the compounds, high-quality polypropylene post-consumer (PCR) recyclates are combined with a bio-based plastic. The recyclate content is between 30% and 60%, depending on the grade, and comes from post-consumer waste streams.

Terralene® rPP thus contributes significantly to a functioning circular economy. The use of plastics based on renewable raw materials conserves fossil resources and sustainably reduces harmful greenhouse gas emissions. Recycling plastics keeps these valuable materials in circulation and thus makes plastic products more sustainable.

At the end of their service life, products made from Terralene® rPP can be recycled in existing disposal systems. The processing conditions and mechanical properties are the same as those of Terralene® PP or fossil PP virgin material. Terralene® rPP grades are characterized by high impact strength combined with toughness and are a direct drop-in solution.