Buckets from Bioplastics

With plastic buckets made from bio-recyclate hybrids, you combine the advantages of renewable raw materials with those of recycled plastics.

We are happy to help.

Sales team

Up for any kind of mud!

The plastic bucket is as versatile as it is simple. Whether as a work tool, as a household and cleaning aid or as a toy in the sandbox. The bucket is unbeaten as a practical container for the simple and short-term transport of liquids and bulk materials.

Terralene® rPP compounds combine the advantages of bioplastics with those of recycled plastics

Usually, both large and small-volume buckets are made from the fossil mass plastic polypropylene. As the topic of recycling and environmental protection is becoming increasingly important for companies, the public sector and, last but not least, consumers, reduction of material use and circularity of plastics is coming more and more into focus. In addition to avoiding waste, the reuse of materials is one of the most important ways of saving and conserving resources. By 2025, 10 million tons of recycled plastics are to be used in new products throughout Europe, according to the EU’s ambitious target.

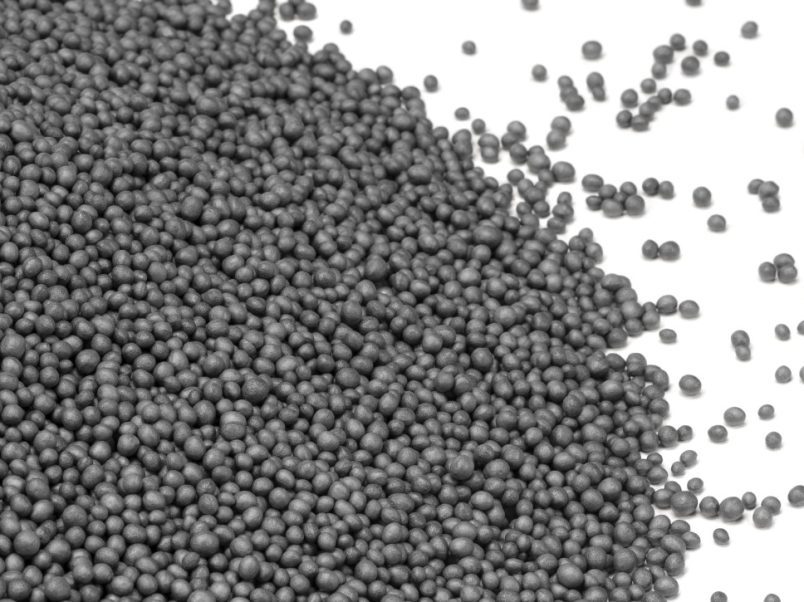

Use our Terralene® rPP granules to manufacture your product, as Terralene® rPP compounds combine the advantages of bioplastics with those of recycled plastics and are therefore a significant innovation.

Combination of high-quality post-consumer (PCR) or post-industrial PP recyclate (PIR) and a bio-based plastic

To produce the compound, a high-quality post-consumer (PCR) or post-industrial PP recyclate (PIR) is combined with a bio-based plastic – depending on the application – so that the bio-based carbon content is around one-third. Depending on the raw material source, Terralene® rPP is available in natural color, light gray or anthracite. The characteristic values and processability correspond to the comparable Terralene® PP grade from virgin material. The range of applications, which is currently still limited to the non-food sector, includes buckets, packaging and technical parts.

Terralene® rPP is recycled in existing systems

This way, Terralene® rPP compounds offer numerous possibilities for the manufacture of sustainable products, completely in line with the circular economy. The use of renewable raw materials conserves fossil resources and reduces harmful greenhouse gas emissions. In addition, plastics are kept in the cycle as a valuable resource. At the end of their service life, products made from Terralene® rPP can be integrated into existing recycling systems.

The processing conditions and mechanical properties correspond to those of Terralene® PP or fossil PP virgin material. Terralene® rPP grades are characterized by high impact strength combined with toughness and are a direct dro