Terralene rPP 3509

Unique combination of recycled and renewable raw materials with the same properties as PP for injection molding

With Terralene® rPP 3509 the following products can be made:

Product information

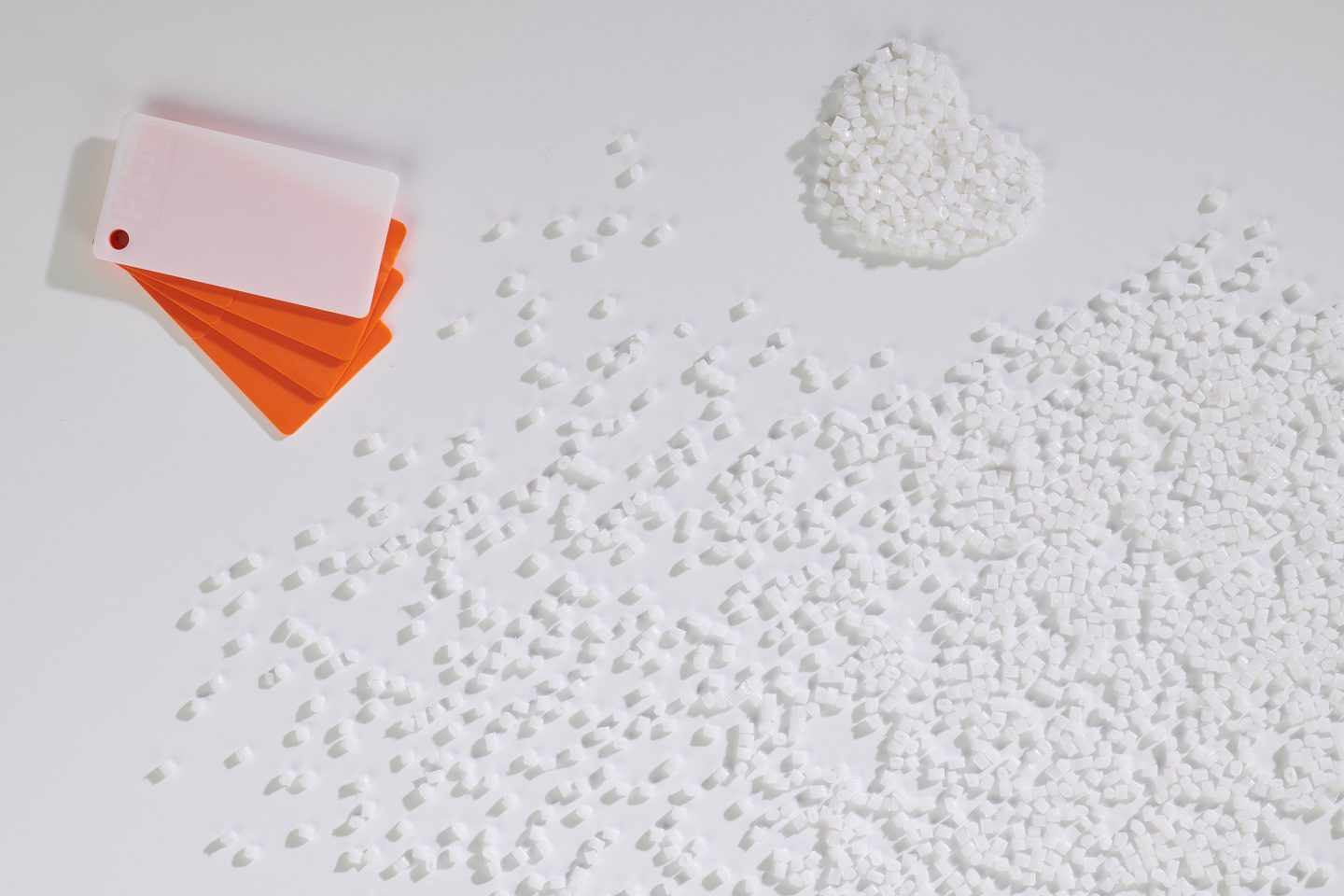

Terralene® rPP 3509 is a compound of a post-consumer or post-industrial PP recyclate with a biobased bioplastic. The proportion of renewable raw materials in this recycled compound is around 33%. The mechanical properties of Terralene® rPP correspond to those of virgin fossil PP. Just like Terralene® PP, it can be processed on existing injection molding equipment and PP molds. The color of the compound can be natural, light grey or anthracite, depending on the recyclate used. Terralene® rPP is currently restricted to non-food contact applications.

Biobased carbon content

33%

Melt flow rate (230°C/2.16kg)

30,0 g/10 min

Processing methods

You can process Terralene® rPP 3509 with these methods: